Welcome to Willis Mechanical’s in-depth exploration of backflow preventers, specifically focusing on the choice between Pressure Vacuum Breakers (PVB) and Reduced Pressure Zone (RPZ) backflow preventers. In the world of commercial plumbing, making an informed decision about backflow prevention is pivotal for maintaining water safety and system reliability. In this comprehensive guide, we’ll delve into the intricacies of each option and address common questions to help you select the most suitable one for your commercial plumbing services.

Understanding Backflow Prevention

Definition and Importance

Backflow is the undesirable reversal of water flow that can potentially contaminate the clean water supply. Backflow prevention devices play a crucial role in maintaining water safety for consumption and various commercial applications.

Role of Backflow Preventers

These devices act as barriers, preventing the reverse flow of water and ensuring that contaminants do not enter the clean water supply. They are indispensable in environments where the risk of contamination is higher.

Pressure Vacuum Breaker (PVB) Explained

Design and Functionality

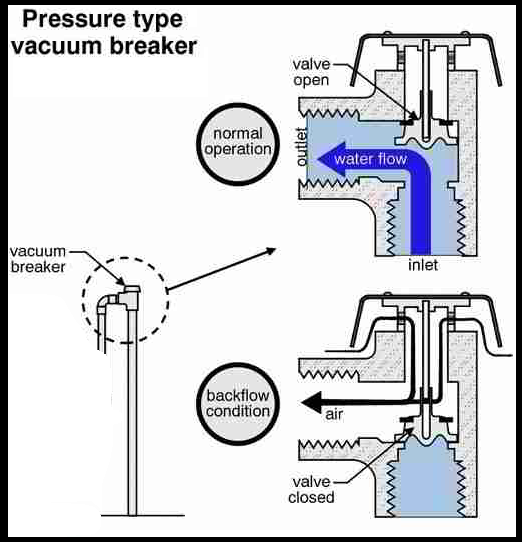

Pressure Vacuum Breakers utilize a spring-loaded check valve and an air relief valve to prevent backflow. This compact device is often installed above ground and finds applications in irrigation systems and outdoor water connections.

Advantages of PVB

- Cost-Effective Solution: PVBs are generally more affordable than other backflow preventers. PVBs are cost-effective due to their straightforward design, which requires fewer materials and components compared to more complex backflow preventers. This simplicity translates to lower manufacturing costs, making PVBs an economical choice for businesses looking to implement efficient yet budget-friendly. The simplicity of their design, along with fewer components, contributes to lower manufacturing and installation costs. backflow prevention solutions.

- Simple Installation and Maintenance: The design of PVBs is inherently simple, making them easy to install and maintain. PVBs feature a spring-loaded check valve that prevents backflow by closing when water flow reverses. An air relief valve is also incorporated to break any potential vacuum. This uncomplicated design facilitates straightforward installation and maintenance procedures, contributing to the overall ease of use. Their above-ground placement simplifies access for inspection and repairs, reducing overall installation and maintenance complexities.

- Suitable for Non-Hazardous Environments: PVBs are well-suited for areas with lower contamination risks. PVBs offer sufficient protection for non-hazardous environments where the risk of contamination is relatively low. In areas with minimal threats, such as residential irrigation systems or outdoor water connections, PVBs provide a cost-effective solution without compromising on safety. While they may not provide the same level of protection as more complex backflow preventers, they are effective in environments where the potential for backflow contamination is minimal.

Limitations of PVB

- Not Ideal for High Hazard Areas: Pressure Vacuum Breakers (PVBs) may not provide the required level of protection in high hazard areas. The straightforward design of PVBs, while effective in many scenarios, may not offer the same advanced protection as more complex backflow preventers. In high hazard areas where the risk of contaminants is substantial, the additional features and redundancy found in other devices, such as Reduced Pressure Zone (RPZ) preventers, are often necessary to meet the stringent safety requirements. The simplicity of their design, while advantageous in terms of affordability and ease of maintenance, may fall short in environments where the risk of contamination is significant.

- Vulnerability to Freezing Temperatures: Pressure Vacuum Breakers (PVBs) are susceptible to damage in freezing temperatures. PVBs are generally installed above ground, exposing them to the elements. In freezing temperatures, any water left within the device can freeze and expand, potentially causing structural damage. This vulnerability raises concerns about the reliability of the backflow preventer in freezing conditions. This vulnerability compromises the overall effectiveness of the backflow preventer. To manage the susceptibility to freezing temperatures, it is crucial to take preventive measures. This includes proper insulation of the PVB, installing the device in a location less exposed to extreme cold, and, in some cases, using heat tape or applying heating methods to protect against freezing. Additionally, regular inspections and winterization procedures before the onset of cold weather can help mitigate the risk of damage.

Reduced Pressure Zones (RPZ) Explained

Design and Functionality

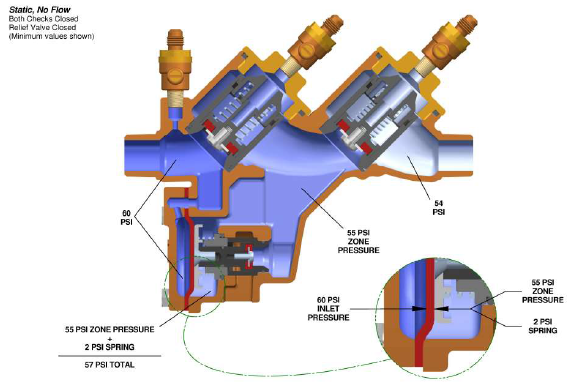

Reduced Pressure Zone backflow preventers utilize two check valves and a pressure differential relief valve. This complex design provides an additional layer of protection, making them suitable for high hazard areas with significant contamination risks.

Advantages of RPZ

- Higher-Level Protection: RPZs offer a more advanced level of protection compared to other backflow preventers. The two check valves and pressure differential relief valve work in tandem to create a secure barrier, ensuring that even in the event of a pressure drop, contaminated water cannot flow back into the clean water supply. The dual-check valve system in RPZs, coupled with the pressure differential relief valve, creates a redundant protection mechanism. In the event of a drop in pressure within the water supply system, RPZs act decisively to prevent any backflow, offering a higher level of protection against potential contaminants.

- Appropriate for High Hazard Environments: RPZs are specifically designed for areas classified as high hazard. These environments include facilities where the potential for water contamination is significant, such as hospitals, laboratories, and chemical processing plants. High hazard areas are those with an increased risk of introducing contaminants into the water supply. Examples include locations where toxic or hazardous substances are used, places with industrial processes involving chemicals, and facilities handling medical waste. RPZs are crucial in such environments to ensure water safety.

- Adaptable to Various Commercial Settings: RPZs can be employed in a variety of commercial settings, providing versatility in their application. This adaptability makes RPZs suitable for a range of businesses and industries with diverse plumbing system requirements. The adaptability of RPZs stems from their robust design and advanced features. Whether it’s a small business, a large industrial facility, or a healthcare institution, RPZs can be tailored to meet the specific needs of different commercial settings. Their flexibility makes them a reliable choice across various industries.

Considerations for RPZ

- Complex Design and Operation: RPZ backflow preventers boast a complex design, incorporating two check valves and a pressure differential relief valve. The check valves, arranged in series, effectively block the reverse flow of water, while the pressure differential relief valve ensures that any drop in pressure activates a relief mechanism, maintaining the integrity of the water supply. The complex design of RPZs involves the intricate interplay of two check valves and a pressure differential relief valve. The check valves are strategically placed in series, ensuring a redundant barrier against backflow. Meanwhile, the pressure differential relief valve adds an extra layer of protection by relieving excess pressure to prevent any compromise in the system.

- Regular Testing and Maintenance Requirements: The intricate nature of RPZs necessitates regular testing and maintenance to ensure consistent performance. Testing typically involves checking the proper functioning of the check valves, confirming the pressure differential relief valve operates as intended, and ensuring all components are free from debris or corrosion. Regular testing involves conducting checks to verify the correct operation of the check valves and pressure differential relief valve. This includes inspecting for any signs of wear, corrosion, or debris that could impede functionality. Additionally, RPZs usually require annual testing by certified professionals to ensure compliance with local regulations and standards.

In the realm of commercial plumbing, choosing between Pressure Vacuum Breakers (PVB) and Reduced Pressure Zone (RPZ) backflow preventers is a decision that demands careful consideration. Each option comes with its unique advantages and limitations, catering to different needs and environments. Pressure Vacuum Breakers, with their affordability and simplicity, offer practical solutions for non-hazardous settings. However, they may fall short in high hazard areas and are vulnerable to freezing temperatures. On the other hand, Reduced Pressure Zone backflow preventers provide a higher level of protection, making them suitable for environments with significant contamination risks. Despite their complexity and potential space requirements, RPZs prove adaptable to various commercial settings. When making this critical decision, businesses must weigh the specific requirements of their plumbing systems and consult with experienced professionals to ensure optimal water safety and system reliability.

Pressure Vacuum Breaker (PVB)

Pros:

- Not ideal for high hazard areas

- Vulnerable to freezing temperatures

Cons:

- Cost-effective solution

- Simple installation and maintenance

- Suitable for non-hazardous environments

Reduced Pressure Zone (RPZ)

Pros:

- Higher-level protection

- Appropriate for high hazard environments

- Adaptable to various commercial settings

Cons:

- Complex design and potential space requirements

- Regular testing and maintenance needed

With a commitment to water safety and system reliability, Willis Mechanical offers expert consultations, personalized assessments, and dependable installation services. Contact us today to ensure your commercial plumbing system is equipped with the most suitable backflow preventer for your specific needs. Your peace of mind and the safety of your water supply are our top priorities. Call us at (678) 966-0094.